Magnetron Sputtering is a powerful technique which can be used to coat virtually any workpiece with a wide range of materials.

In our laboratory, we use Magnetron Sputtering Unit G500M made by

SIDRABE and equiped with

MELEC Pulse Power Controller for HiPIMS.

DC MAGNETRON SPUTTERING

The substrate is placed at room temperature in a low-pressure chamber between two electrodes (the cathode and anode).

A large DC potential is applied between the electrodes, which causes a plasma and ionization of the gas (e.g., argon) between

the electrodes. The ions bombard the cathode (named the target) causing atoms to be knocked off the target and condense on the

substrate surface. A strong magnetic field is applied to contain the plasma near the surface of the target to increase the deposition

rate. The process is typically performed on one side of the substrate at a time and can only be used to deposit conductive materials.

RF MAGNETRON SPUTTERING

The substrate is placed in a low-pressure chamber between two electrodes. The electrodes are driven by an RF power source, which generates a plasma and

ionizes the gas (e.g., argon) between the electrodes. A DC potential is used to drive the ions towards the surface of one of the electrodes (named the target) causing atoms to be knocked off the target and condense on the substrate surface. A strong magnetic field is applied to contain the plasma near the surface of the target to increase the deposition rate. The process is typically performed on one side of the substrate at a time.

HiPIMS

High power impulse magnetron sputtering - HiPIMS (or sometimes named as HPPMS) is a pulsed DC sputtering technique utilizing high power density peaks of typically more than 100 W per square cm at a sufficiently low time-averaged power density in order to avoid target overheating. This results in a high density discharge and, consequently, in a high degree of ionization of the sputtered material. This makes HiPIMS a very attractive deposition technique for enhancing and tailoring coating properties. For instance, a high number of metal ions in the deposition flux was found to be beneficial in substrate pre-treatment for adhesion improvement, and in the fabrication of dense, defect-free coatings with low surface roughness.

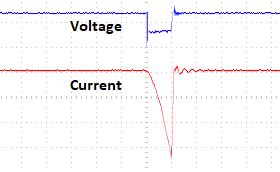

HiPIMS unipolar mode |

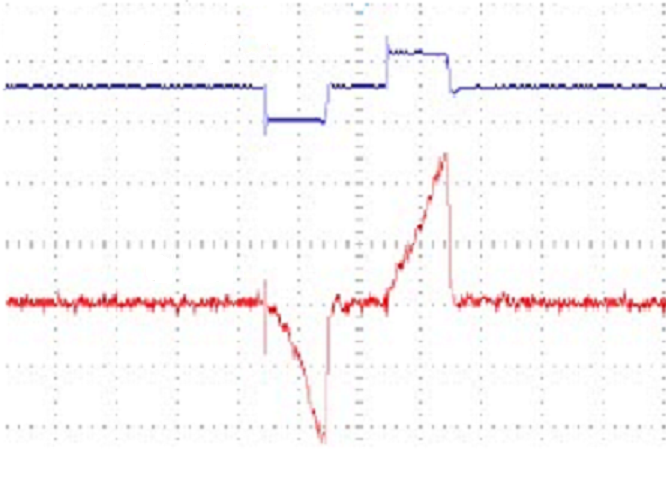

HiPIMS bipolar mode |

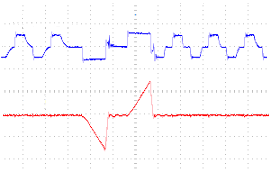

HiPIMS bipolar mode + RF pulses |

USEFUL LINKS

Sputter Deposition in Wikipedia

What is sputtering?

NIST Atomic Spectra Database.

Spectra of Gas Discharges.

SIDRABE - vacuum systems.

GroGlass - optical coatings on glass.

LESKER - vacuum systems.

|